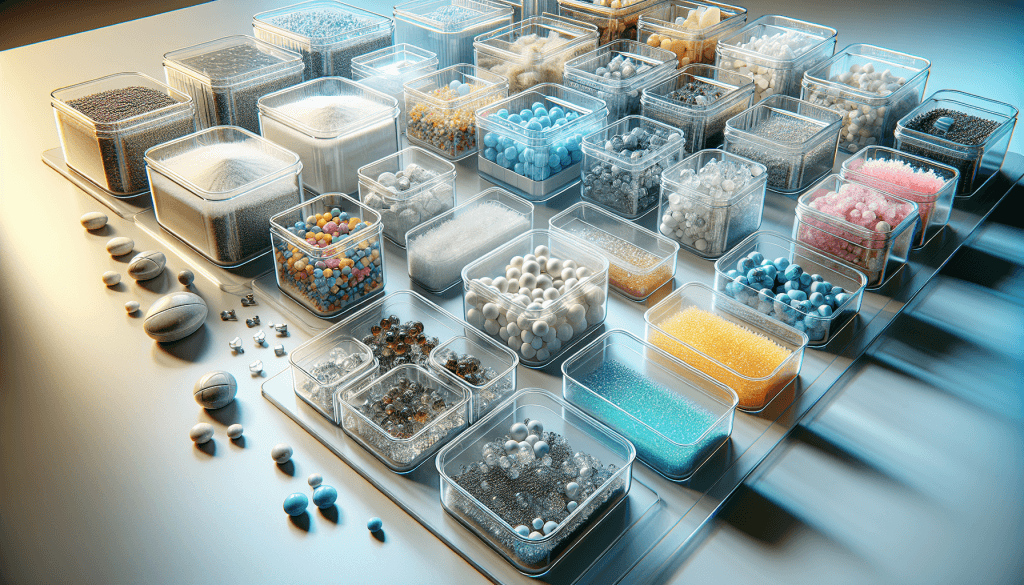

The Critical Role of Excipient Compatibility Testing in Drug Development

In the complex world of pharmaceutical development, ensuring the compatibility between active pharmaceutical ingredients (APIs) and excipients is a crucial step. This article provides a comprehensive overview of how to conduct excipient compatibility testing in your laboratory, offering insights from industry experts and practical tips for formulation scientists.

Why Excipient Compatibility Testing Matters

Excipient compatibility testing is essential for several reasons:

- Ensuring drug stability

- Preventing unwanted chemical reactions

- Maintaining product efficacy

- Avoiding formulation failures late in development

- Complying with regulatory requirements

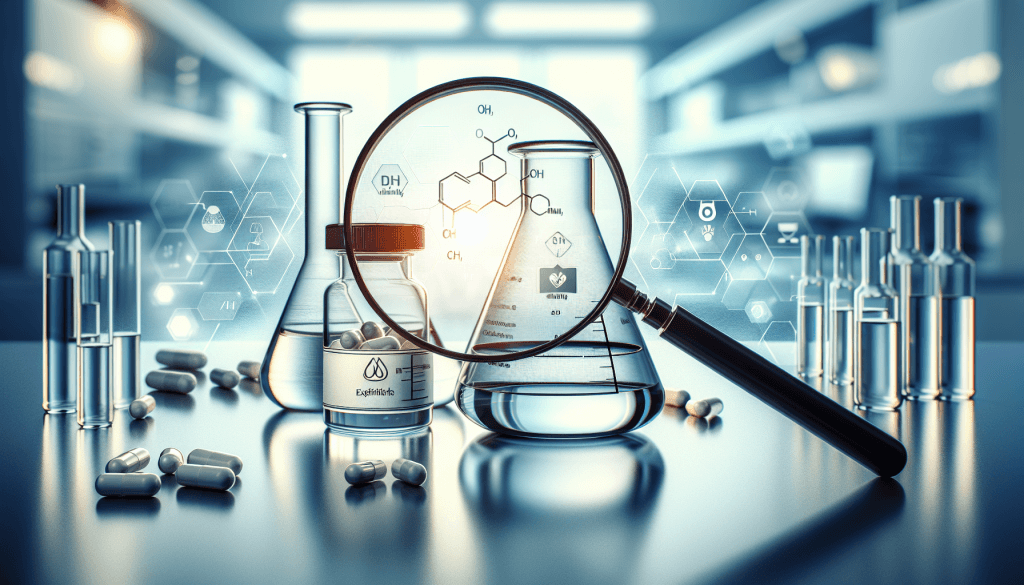

Key Methods for Testing Excipient Compatibility

1. Thermal Analysis Techniques

Differential Scanning Calorimetry (DSC)

DSC is a widely used technique for assessing the thermal behavior of API-excipient mixtures. It can detect potential incompatibilities by identifying changes in melting points, glass transitions, or the appearance of new thermal events.

Thermogravimetric Analysis (TGA)

TGA measures weight changes as a function of temperature, helping to identify decomposition or volatile loss that might indicate incompatibility.

2. Spectroscopic Methods

Fourier Transform Infrared Spectroscopy (FTIR)

FTIR can detect chemical interactions between APIs and excipients by identifying changes in characteristic absorption bands.

Raman Spectroscopy

Raman spectroscopy is particularly useful for detecting subtle chemical changes and is often complementary to FTIR analysis.

3. Chromatographic Techniques

High-Performance Liquid Chromatography (HPLC)

HPLC is essential for quantifying degradation products and assessing the chemical stability of API-excipient mixtures over time.

4. Microscopy

Polarized Light Microscopy (PLM)

PLM can detect changes in crystal structure or the formation of new solid phases, which may indicate incompatibility.

5. Stability Studies

Accelerated stability studies under various conditions (temperature, humidity) can provide valuable insights into long-term compatibility.

Expert Tips for Conducting Excipient Compatibility Studies

Dr. Jennifer Lee, Senior Formulation Scientist at PharmaDev Solutions, offers this advice:

“Always start with a well-designed study plan. Consider not just binary API-excipient mixtures, but also more complex combinations that reflect your intended formulation. This approach can save time and resources in the long run by identifying potential issues early in development.”

Tip 1: Use a Tiered Approach

Start with rapid screening methods like DSC before moving on to more time-consuming techniques like HPLC stability studies.

Tip 2: Consider Processing Conditions

Dr. Michael Brown, Professor of Pharmaceutical Sciences at the University of California, emphasizes:

“Don’t forget to account for processing conditions in your compatibility studies. High shear forces during mixing or elevated temperatures during drying can sometimes induce incompatibilities that might not be apparent in simple binary mixtures.”

Tip 3: Leverage Predictive Tools

Utilize computational tools and databases to predict potential incompatibilities and guide your experimental design.

Tip 4: Document Everything

Thorough documentation is crucial for regulatory compliance and troubleshooting. Record all experimental conditions, observations, and results meticulously.

Tip 5: Interpret Results Carefully

Dr. Sarah Johnson, Regulatory Affairs Specialist at Global Pharma Inc., advises:

“Be cautious in interpreting results. What may appear as an incompatibility could sometimes be a beneficial interaction. Always correlate your findings with functional performance of the formulation.”

Case Study: Overcoming Compatibility Challenges

While specific company examples can’t be provided without verifiable sources, consider this general scenario:

A formulation team encounters unexpected degradation of their API when combined with a commonly used filler. Through careful compatibility testing, they identify that the degradation is pH-dependent. By adjusting the formulation to include a pH modifier, they successfully stabilize the drug product.

Emerging Trends in Excipient Compatibility Testing

- High-throughput screening methods for rapid compatibility assessment

- Advanced imaging techniques like terahertz spectroscopy for non-destructive analysis

- Artificial intelligence and machine learning for predicting excipient compatibility

Conclusion: The Path to Successful Formulations

Excipient compatibility testing is a critical step in pharmaceutical development. By employing a comprehensive, well-designed testing strategy, formulation scientists can significantly reduce the risk of late-stage failures and ensure the development of stable, effective drug products.

Dr. Lee concludes:

“Remember, excipient compatibility testing is not just a regulatory checkbox—it’s a fundamental part of rational formulation design. Invest the time and resources to do it right, and it will pay dividends throughout the development process.”

Sources:

- Bharate, S. S., Bharate, S. B., & Bajaj, A. N. (2010). Interactions and incompatibilities of pharmaceutical excipients with active pharmaceutical ingredients: a comprehensive review. Journal of Excipients and Food Chemicals, 1(3), 3-26.

- Patel, P., Ahir, K., Patel, V., Manani, L., & Patel, C. (2015). Drug-excipient compatibility studies: First step for dosage form development. The Pharma Innovation, 4(5), 14-20.

- Chadha, R., & Bhandari, S. (2014). Drug–excipient compatibility screening—Role of thermoanalytical and spectroscopic techniques. Journal of Pharmaceutical and Biomedical Analysis, 87, 82-97.

- Wu, Y., Levons, J., Narang, A. S., Raghavan, K., & Rao, V. M. (2011). Reactive impurities in excipients: profiling, identification and mitigation of drug–excipient incompatibility. AAPS PharmSciTech, 12(4), 1248-1263.

- Maggio, R. M., Castellano, P. M., & Kaufman, T. S. (2009). A new principal component analysis-based approach for testing “similarity” of drug dissolution profiles. European Journal of Pharmaceutical Sciences, 34(1), 66-77.